In this article, I will explain the importance of periodic testing of your ESD workwear to ensure that the garment is staying within the compliance parameters and in accordance with IEC 61340-4-9:2016 and ANSI/ESD STM2.1:2018

What’s so special about ESD clothing fabrics?

What makes an ESD garment different than a standard warehouse lab coat or polo shirt for example, is that within the material is a conductive fibre comprising of a carbon-infused monofilament incorporated as a grid of typically 4mm to 5mm. With lighter ESD materials this can be seen. The ESD garment manufacturer will also quote the percentage of carbon in the material; typically, we will not stock a garment of less than 2% conductive carbon content. As an article of clothing consists of different panels i.e. the main body section, arms, and cuffs, the manufacturer needs to ensure that these fabric panels are correctly stitched to ensure conductive continuity runs through the finished item. A conductive thread is used for this purpose.

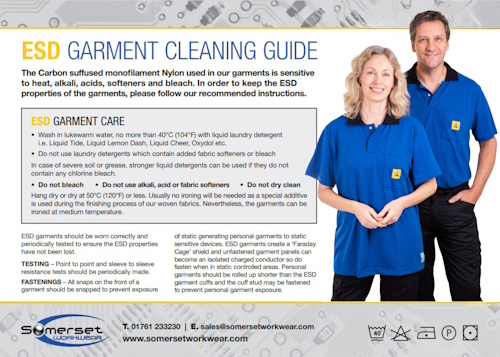

The cleaning of ESD clothing

Your ESD garment will go through multiple washing cycles during the garment life and the importance of how it is washed cannot be stressed enough. The carbon monofilament can be affected by heat, chemicals, and high heat or an incorrect cleaning liquid will have an impact on the life of the garment. The manufacturer may quote a garment life of 40, 50 or more industrial washes, but if the cleaning is not performed within certain parameters, the garment life will be reduced. We have seen examples of garments washed in excess of 70-80°C by commercial cleaning companies when an ESD fabric should be washed at 40°C. If you are using a commercial cleaning company, we do recommend that you check with them to see how they are cleaning and that they also have the capability to test the garments.

So how do you know if your garment is or is not compliant?

When a static control garment leaves the factory, it would have been manufactured with the material of a specific resistance. The standard sets this as being <1.0 x 10(11) ohms, but that should be considered the very upper limit for acceptance. Don’t forget that with wearing and even with correct washing, the fabric conductivity will change; having a new garment with a high resistance value will mean it will be non-compliant much quicker.

So how do you know if your ESD garment is compliant and meets the ESD standards? Testing is the answer.

Sleeve to sleeve and point to point testing

These are two simple test methods to perform by taking a resistance measurement from cuff to cuff or panel to panel verifying the continuity through the arms to the body section and also checking the panel sewing. We supply ESD test kits specifically for these test procedures and incorporate a calibrated test meter (a calibration certificate is supplied), a set of clamps, leads, and an handy ESD storage box.

Firstly, ensure that the article of ESD clothing is not placed on an ESD static dissipative workbench or matting so that it is isolated from ground. With each clamp connected to the test meter, attach them to different parts of the garment, sleeve to sleeve or sleeve to body, and with the voltage applied a measurement can be recorded.

At Somerset Workwear we can supply a Certificate of Conformity stating the test procedure and results prior to sending your garment order to you. Please request this if it is a requirement.

Conclusion

Being an easy-to-perform test method means that having a planned periodic testing routine enables you to check the garments are compliant. We want you to get the maximum life from your ESD workwear and by performing these simple tests you can ensure you know the condition of the garment and that it is fit for purpose.